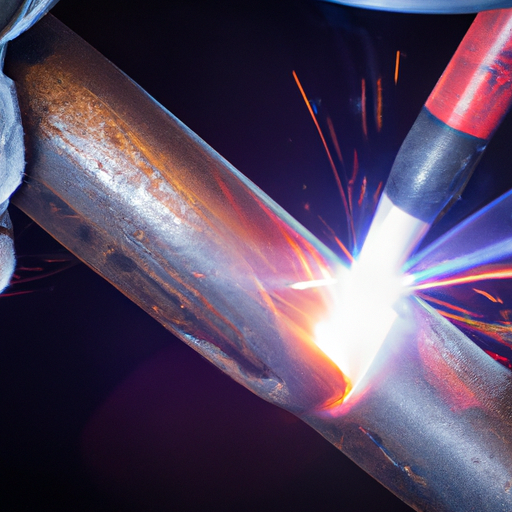

In the world of welding, working with different metal thicknesses can present unique challenges. Ensuring a strong and secure weld requires careful consideration of factors such as heat distribution, joint design, and electrode selection. This comprehensive guide will provide you with the essential knowledge and techniques needed to successfully weld various metal thicknesses. Whether you’re a seasoned professional or just starting out in the world of welding, this guide will serve as your authoritative resource, empowering you to tackle any welding project with confidence and precision.

Understanding Metal Thicknesses

Metal thickness refers to the measurement of the thickness or gauge of a metal sheet or section. It is an essential aspect of welding, as different thicknesses require different welding techniques and considerations. Understanding metal thicknesses is crucial for achieving strong, durable, and high-quality welds.

Types of Metals in Welding

In welding, two main categories of metals are commonly used: ferrous metals and non-ferrous metals. Ferrous metals contain iron as the main component, such as carbon steel and stainless steel. Non-ferrous metals, on the other hand, do not contain iron and include metals like aluminum, copper, and titanium. Each of these metals possesses unique properties and characteristics that impact the welding process.

Common Metals Used in Welding

Some of the most commonly used metals in welding include carbon steel, stainless steel, aluminum, and copper. Carbon steel is highly versatile and widely used due to its affordability and strength. Stainless steel is chosen for its corrosion resistance and aesthetic appeal. Aluminum is lightweight and offers excellent conductivity, making it suitable for various applications. Copper is valued for its electrical and thermal conductivity, making it commonly used in electronics and plumbing industries.

Welding Techniques for Different Metal Thicknesses

Matching the welding process to the metal thickness is crucial to achieve optimal results. Different types of welding processes, such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and Stick welding, have varying suitability for different metal thicknesses. TIG welding is often preferred for thin metal sheets due to its precise control and ability to produce clean welds. MIG welding is more suitable for thicker metal sections due to its high deposition rate and productivity.

Welding Thin Metal Sheets

Welding thin metal sheets presents unique challenges due to their lower heat capacity and increased vulnerability to distortion. TIG welding is a commonly used technique for thin metal sheets, as it allows for better control and reduces the risk of burning through the material. When welding thin sheets, it is crucial to use lower heat settings, maintain a steady hand, and move quickly to minimize heat buildup and distortion. Additionally, using filler metals with a lower melting point can help prevent burn-through.

Welding Medium Thickness Metals

Medium thickness metals typically fall within the range of 1/8 inch to 1 inch. When welding medium thickness metals, several techniques are commonly employed. These include MIG welding, TIG welding, and Stick welding. While MIG welding offers high deposition rates, TIG welding enables precise control for thinner sections within the medium thickness range. Proper heat control and distortion prevention techniques, such as preheating and joint preparation, are crucial for successful welding in this range.

Welding Thick Metal Sections

Welding thick metal sections presents its own set of challenges. Thick metal sections, with a thickness beyond 1 inch, often require preheating to ensure proper penetration and minimize the risk of cracking. MIG welding is commonly used for welding thick metal sections due to its high deposition rates and deep penetration capabilities. It is essential to select the appropriate joint preparation and welding techniques to ensure proper fusion and structural integrity.

Multi-Pass Welding for Varying Thicknesses

Multi-pass welding is utilized when welding varying thicknesses within a single weld joint. It involves completing the welding process in multiple passes to ensure thorough fusion and strength. The techniques employed in multi-pass welding depend on the metal thicknesses involved. For instance, a combination of preheating and post-weld heat treatment may be necessary to prevent cracking and control distortion. Quality control and inspection play a vital role in ensuring the integrity of multi-pass welds.

Matching Filler Metal to Different Thicknesses

Selecting the right filler metal is crucial in achieving strong and durable welds for different metal thicknesses. Factors such as compatibility, strength, and melting temperature must be considered when choosing the appropriate filler metal. For thin metal sheets, filler metals with lower melting points are often preferred to prevent burn-through. In contrast, for thicker sections, filler metals with higher tensile strength may be required to ensure adequate strength and load-bearing capacity.

Preventing Distortion and Warping

Distortion, or the change in shape and dimensions of welded metal, is a common concern in welding processes. Several strategies can help minimize distortion when working with different metal thicknesses. Proper joint design, including the use of bevels and chamfers, can distribute heat more evenly and reduce the risk of distortion. Additionally, employing techniques such as back-stepping and peening can help control the cooling rate and minimize distortion. Post-weld heat treatment methods, such as stress relieving, can also aid in reducing distortion.

Safety Considerations for Welding Different Thicknesses

Welding poses various hazards, regardless of the metal thickness being welded. It is crucial to prioritize safety at all times and adhere to best practices. Protective gear and equipment, including welding helmets, gloves, and aprons, should be worn to prevent exposure to UV radiation, sparks, and flying debris. Hazards such as electrical shocks, fumes, and noise should be mitigated through proper ventilation, grounding, and use of personal protective equipment. Ongoing training, certification, and regular equipment maintenance are essential for safe welding practices.

In conclusion, understanding metal thicknesses and employing appropriate welding techniques are fundamental to achieving successful welds across different metal thicknesses. By considering the characteristics and challenges associated with welding thin, medium, and thick metal sections, and ensuring the selection of suitable filler metals, welders can produce strong, durable, and high-quality welds. Additionally, prioritizing safety and implementing strategies to minimize distortion further contribute to the overall success of welding projects. With a comprehensive understanding of welding different metal thicknesses, welders can confidently tackle various welding applications and achieve optimal results.