This article serves as a comprehensive guide on flux-core welding stainless steel, aimed at establishing your expertise in the field of welding. Through this guide, you will gain a thorough understanding of the key aspects involved in flux-core welding stainless steel, enabling you to tackle complex welding projects with confidence and precision. Whether you are a seasoned welder or a novice in the realm of welding, this guide will equip you with the knowledge and techniques necessary to successfully weld stainless steel using the flux-core method.

Flux-Core Welding Stainless Steel Guide

What is Flux-Core Welding?

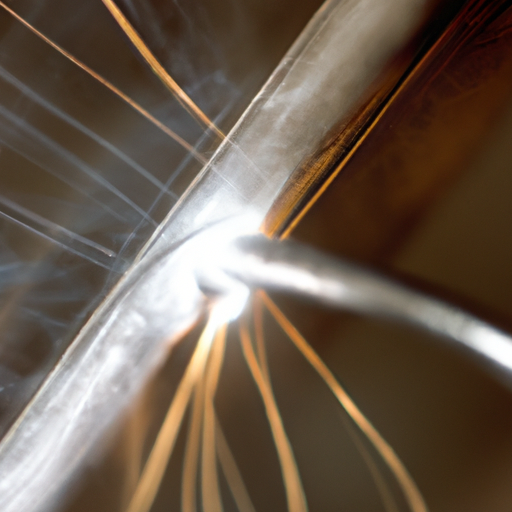

Flux-core welding, also known as flux-cored arc welding (FCAW), is a welding process commonly used for stainless steel fabrication. It is a variation of the traditional arc welding methods that involves the use of a flux-filled wire electrode. The flux in the wire creates a protective shield around the arc, preventing atmospheric contamination of the weld.

Advantages of Flux-Core Welding

Flux-core welding offers several advantages when it comes to welding stainless steel. Firstly, it allows for deep penetration, resulting in strong and durable welds. The higher deposition rates of flux-core welding also mean that larger and thicker stainless steel pieces can be welded more efficiently.

Another advantage is the versatility of flux-core welding. It can be performed in all positions, including overhead welding, making it suitable for a wide range of stainless steel welding applications. Additionally, since the flux in the wire acts as a shielding agent, there is no need for an external shielding gas, which reduces costs and simplifies the welding process.

Disadvantages of Flux-Core Welding

Despite its advantages, flux-core welding has a few limitations. One of the main disadvantages is the production of more spatter compared to other welding methods. This can result in a messier weld and may require additional cleaning and post-welding work.

Additionally, flux-core welding may require more skill and experience to achieve optimal results. The higher heat input and potential for distortion in the weld area can make it challenging for beginners. Proper technique and control are crucial to prevent issues such as burn-through or insufficient fusion.

Choosing the Right Flux-Core Wire

Selecting the correct flux-core wire is vital for successful stainless steel welding. Factors to consider include the type and grade of stainless steel, the desired weld characteristics, and the specific application. Flux-core wires are available in various compositions, such as those designed for austenitic or duplex stainless steels.

Consulting with welding experts or referring to the manufacturer’s recommendations can help in identifying the most suitable flux-core wire for a particular stainless steel welding project. Ensuring proper compatibility between the wire and the base metal is essential for achieving strong and durable welds.

Preparing Stainless Steel for Flux-Core Welding

Proper preparation of the stainless steel surface is crucial for successful flux-core welding. Before welding, it is important to clean the stainless steel thoroughly to remove any contaminants, such as dirt, grease, or oxide layers. This can be done using various methods, such as wire brushing, grinding, or chemical cleaning.

Furthermore, proper joint design and fit-up are essential to ensure optimal penetration and fusion. The choice of joint configuration, such as butt joints or lap joints, depends on the specific welding application. Beveling the edges of the stainless steel pieces may also be necessary to allow for proper penetration of the weld.

Setting Up the Flux-Core Welding Machine

Proper setup of the flux-core welding machine is essential for achieving optimal results. Begin by selecting the appropriate welding machine and power source suitable for stainless steel welding. Consult the manufacturer’s guidelines for the recommended voltage, wire feed speed, and other settings.

Ensure that the welding machine is in good working condition and that all connections are secure. Check the gas supply, if applicable, and ensure that the flow rate is appropriate for the flux-core wire being used. It is also important to verify that the polarity is correctly set for flux-core welding.

Flux-Core Welding Techniques

Flux-core welding requires specific techniques to achieve the desired weld quality and appearance. Here are some key techniques to keep in mind:

- Maintain a consistent travel speed to ensure even weld bead formation and proper fusion.

- Watch the welding puddle closely. Adjust the heat input and wire feed speed accordingly to control the size of the puddle and prevent issues like burn-through or insufficient penetration.

- Use the proper weaving or oscillation technique to distribute the heat evenly across the weld area. This helps prevent distortion and ensures proper bonding.

- Practice proper start and stop techniques to ensure smooth transitions and avoid defects at the beginning and end of the weld.

Welding Positions for Flux-Core Welding Stainless Steel

Flux-core welding can be performed in all welding positions, including flat, horizontal, vertical, and overhead. Each position requires different techniques and considerations:

- Flat Position: The flat position is the easiest position for flux-core welding stainless steel. Maintain a consistent travel speed and ensure proper penetration.

- Horizontal Position: In the horizontal position, gravity can affect the weld pool. Use a slight upward angle and slightly faster travel speed to compensate for sagging.

- Vertical Position: Vertical welding can be challenging due to the potential for gravity-induced sagging and poor penetration. Employ a slight weaving motion and maintain proper electrode angle for better control.

- Overhead Position: Overhead welding requires steady hands and precise technique. Use a slightly shorter arc length, slower travel speed, and smaller wire feed speed for better control and reduced spatter.

Common Mistakes to Avoid in Flux-Core Welding

To achieve high-quality welds in flux-core welding stainless steel, it is essential to avoid common mistakes that can compromise the integrity of the welds. Some common mistakes to avoid include:

- Insufficient cleaning of the stainless steel surface before welding, leading to poor fusion and contamination.

- Incorrect wire feed speed and voltage settings, resulting in improper heat input and weld quality.

- Inconsistent travel speed, leading to uneven weld bead formation and poor fusion.

- Improper joint fit-up and preparation, resulting in reduced penetration and weaker welds.

- Neglecting safety precautions, such as wearing proper protective gear and ensuring proper ventilation in the welding area.

Safety Precautions for Flux-Core Welding Stainless Steel

Safety should always be a top priority when engaging in flux-core welding stainless steel. Here are some important safety precautions to follow:

- Always wear personal protective equipment (PPE), including welding gloves, safety glasses or a welding helmet, and flame-resistant clothing.

- Ensure proper ventilation in the welding area to remove fumes and gases generated during the welding process.

- Avoid welding in confined spaces without proper ventilation or gas monitoring equipment.

- Be aware of the hazards of ultraviolet (UV) radiation emitted during the welding process. Use appropriate UV protection, such as a welding helmet with the proper shade, to protect your eyes and skin.

- Store and handle welding equipment, including flux-core wires and gas cylinders, according to manufacturer guidelines and local safety regulations.

By following these safety precautions, welders can protect themselves and others from potential hazards associated with flux-core welding stainless steel and ensure a safe working environment.

In conclusion, flux-core welding is a valuable technique for welding stainless steel, offering advantages such as deep penetration, high deposition rates, and versatility. However, it is important to choose the right flux-core wire, properly prepare the stainless steel surface, and follow correct welding techniques and safety precautions. With the right knowledge and skills, welders can achieve strong and durable welds in stainless steel using flux-core welding methods.