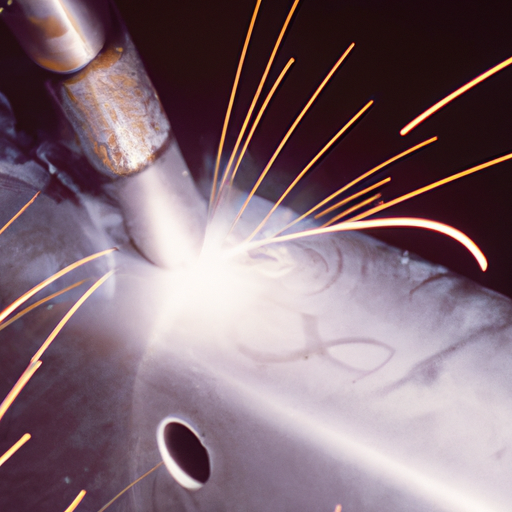

Aluminum welding is a critical process that demands expertise and precision. However, an issue that often arises during this type of welding is porosity. Porosity refers to the presence of tiny holes or voids in the weld, compromising its strength and integrity. To prevent porosity in aluminum welding, understanding its causes and implementing appropriate precautions is crucial. This article will explore the common factors contributing to porosity in aluminum welding and provide valuable insights on how to avoid this issue, ensuring high-quality welds that meet industry standards.

Preventing Porosity in Aluminum Welding

Aluminum welding is a common process used in various industries, including aerospace, automotive, and construction. Porosity, or the presence of gas pockets in the weld, can compromise the integrity and strength of the joint. It is essential to understand the causes of porosity and implement preventive measures to ensure high-quality aluminum welds.

Understanding the Causes of Porosity

Porosity in aluminum welding can occur due to several factors. One of the primary causes is inadequate gas shielding. Aluminum is highly reactive and readily oxidizes when exposed to air. To prevent this, a shielding gas, typically argon, is used to create a protective atmosphere around the weld. Inadequate gas coverage or improper gas flow can result in oxygen and moisture contamination, leading to porosity.

Another factor contributing to porosity is the selection of improper filler material. The filler metal used in aluminum welding should match the base metal’s composition and have a suitable alloying element. Choosing the wrong filler material can result in gas solubility mismatch, leading to porosity.

Ensuring Proper Gas Shielding

To prevent porosity in aluminum welding, proper gas shielding is crucial. One of the key steps is to create a gas envelope around the welding area. This can be achieved by using a gas cup or nozzle that provides sufficient coverage. It is essential to maintain a consistent gas flow rate throughout the welding process to prevent air intrusion.

Additionally, using a high-quality shielding gas, such as pure argon or a mixture of argon and helium, helps minimize the risk of porosity. These gases provide excellent inertness and prevent oxidation of the molten aluminum, resulting in cleaner welds.

Selecting the Right Filler Material

When it comes to filler material selection in aluminum welding, matching the composition and alloying elements of the base metal is crucial. This ensures compatibility and minimizes the risk of porosity. It is recommended to consult welding procedure specifications (WPS) or industry standards to determine the appropriate filler metal for each specific aluminum alloy.

Furthermore, using a filler material with deoxidizing elements, such as silicon or magnesium, can help mitigate porosity. These elements scavenge any remaining oxygen or moisture, reducing the chances of porosity formation.

Optimizing Welding Parameters

Optimizing the welding parameters is essential in preventing porosity in aluminum welding. This includes adjusting the current, voltage, travel speed, and welding technique to create a stable and controlled process. In general, a lower current and voltage setting is preferred to minimize the amount of heat input, reducing the risk of porosity formation.

Maintaining a consistent travel speed is also crucial. Rapid or erratic movement can result in inadequate gas shielding, leading to porosity. It is recommended to practice a smooth and steady motion to ensure proper gas coverage and heat distribution.

Proper Cleaning and Surface Preparation

Proper cleaning and surface preparation play a significant role in preventing porosity in aluminum welding. Contaminants, such as oil, grease, dirt, or oxides, must be removed before initiating the welding process. Failure to do so can result in impurities being trapped in the weld, leading to porosity.

Mechanical methods, such as wire brushing or grinding, can be used to remove surface contaminants. It is essential to clean not only the immediate welding area but also the surrounding region to prevent contamination during the process.

Avoiding Moisture Contamination

Moisture contamination can significantly contribute to porosity formation in aluminum welding. Water or moisture in the form of humidity can react with molten aluminum, liberating hydrogen gas, which is a major cause of porosity. It is crucial to ensure a dry welding environment and minimize exposure to moisture during the welding process.

Preheating the base metal or using a preheating oven can help remove any existing moisture, ensuring a dry surface for welding. Additionally, using a moisture meter or hygrometer can help monitor the humidity levels in the welding area and take preventive measures accordingly.

Minimizing Welding Speed

The welding speed plays a vital role in preventing porosity in aluminum welding. Welding too fast can result in inadequate gas shielding and insufficient heat input, leading to porosity formation. Slowing down the welding speed allows for better gas coverage and proper fusion between the base metal and filler material.

It is crucial to strike a balance and find an optimal welding speed that ensures both sufficient heat input and proper gas shielding, thereby minimizing the risk of porosity.

Controlling Heat Input

Controlling the heat input during aluminum welding is essential in preventing porosity. Excessive heat can cause the molten aluminum to become more fluid, promoting gas absorption and porosity. It is recommended to use a lower welding current and voltage setting to reduce heat input and minimize the risk of porosity formation.

Additionally, employing pulse welding techniques or using a pulsed current can help regulate heat input and prevent overheating. These techniques provide controlled heat input and allow for better control over the welding process, reducing the chances of porosity.

Using the Correct Welding Technique

Applying the correct welding technique is crucial in preventing porosity in aluminum welding. The choice of welding technique depends on the specific requirements and the welding position. Some commonly used techniques for aluminum welding include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and laser welding.

TIG welding is widely used for aluminum due to its precise control and excellent bead appearance. MIG welding offers higher deposition rates, making it suitable for thicker aluminum sections. Laser welding provides a concentrated heat source and can be advantageous for precise and intricate welds.

Selecting the most appropriate welding technique based on the specific application can help minimize the risk of porosity and produce high-quality aluminum welds.

Post-Weld Inspection and Remedies

After completing the welding process, it is crucial to perform a thorough post-weld inspection to detect any signs of porosity. Visual inspection, liquid penetrant testing, or radiographic testing can be employed to identify any defects or imperfections.

If porosity is detected, appropriate remedies can be implemented. This may involve re-welding the affected area, modifying the welding parameters, or improving the gas shielding and cleaning processes. Qualified welding personnel should assess the extent of porosity and determine the most suitable remedial action.

In conclusion, preventing porosity in aluminum welding requires a comprehensive approach encompassing proper gas shielding, filler material selection, optimization of welding parameters, cleaning and surface preparation, and control of heat input. By understanding the causes of porosity and implementing preventive measures, high-quality aluminum welds can be achieved, ensuring the integrity and reliability of welded structures in various industries.