Titanium welding presents a unique set of challenges due to the metal’s high strength and low thermal conductivity. In order to achieve a successful weld, proper preparation is crucial. This article will guide you through the essential steps to take before embarking on a titanium welding project. By following these guidelines, you will enhance your knowledge and skills as an authority in welding, ensuring optimal results and safety when working with this formidable material. So let’s embark on a journey to explore the meticulous preparation required for titanium welding.

Titanium Welding Preparation Steps

Welding titanium requires careful preparation to ensure a successful and efficient welding process. By following a series of vital steps, you can enhance the quality of the weld and minimize any potential issues. This comprehensive article will guide you through the essential preparation steps, helping you achieve optimal results in your titanium welding projects.

Choosing the Right Welding Method

Before embarking on a titanium welding project, it is crucial to select the appropriate welding method for the job. Titanium can be welded using various methods, including tungsten inert gas (TIG) welding, plasma arc welding, and electron beam welding. Each method has its advantages and limitations, and it is essential to consider factors such as the required weld strength, thickness of the material, and budget constraints when making your decision.

Understanding the Properties of Titanium

Titanium possesses unique properties that differentiate it from other metals, making it a popular choice in various industries. Before welding titanium, it is important to have a good understanding of its properties. Titanium is highly reactive with oxygen, nitrogen, and hydrogen, which can lead to the formation of brittle compounds and porosity in the weld. It also has a high melting point and is prone to distortion if not heated and cooled properly during the welding process.

Ensuring Proper Ventilation

Titanium welding generates fumes and gases that can be hazardous if inhaled. To ensure the safety of the welder and maintain a healthy work environment, proper ventilation is crucial. The welding area should have sufficient airflow and ventilation systems in place to remove smoke, fumes, and gases. Before starting any welding operation, make sure you have a well-ventilated space or use fume extraction equipment to prevent the accumulation of harmful substances.

Gathering Essential Tools and Equipment

Before commencing the welding process, it is essential to gather all the necessary tools and equipment. These may include a welding machine, welding torch, filler materials, tungsten electrodes, stainless steel wire brush, gloves, safety glasses, welding helmet, and fire extinguisher. Having all the required tools and equipment readily available will enhance your efficiency and ensure a smooth welding operation.

Cleaning the Welding Area

A clean welding area is vital to achieve high-quality welds. Before starting the titanium welding process, it is crucial to thoroughly clean the welding area. Remove any dirt, debris, or grease that may contaminate the weld. Use a stainless steel wire brush to clean the surface, ensuring it is free from any contaminants that can compromise the quality of the weld.

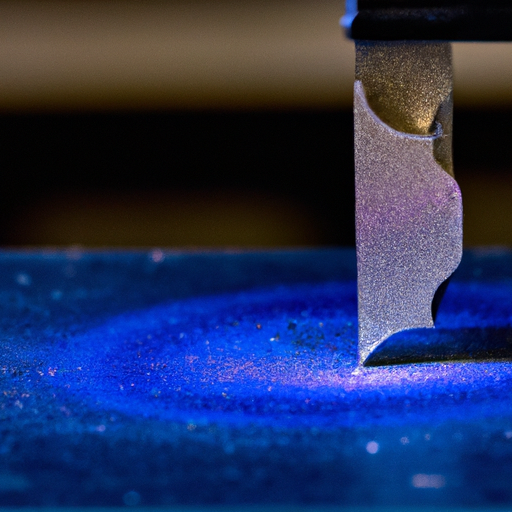

Preparing the Titanium Surface

To achieve a sound weld, proper preparation of the titanium surface is essential. Begin by removing any oxide layer or surface impurities using a stainless steel wire brush or chemical cleaning solution specifically designed for titanium. Ensure that the surface is clean, dry, and free from any contamination before initiating the welding process. Proper surface preparation is critical for achieving strong and durable welds.

Securing the Workpiece

Before welding, it is important to securely position and align the workpiece. This will ensure stability and prevent any movement during the welding process, which can lead to defects and an inferior weld. Use clamps or fixtures to hold the workpiece firmly in place, allowing for precise control during the welding operation. Carefully consider the positioning and alignment to achieve the desired weld joint configuration.

Setting Up the Welding Machine

Proper setup of the welding machine is crucial for successful titanium welding. Ensure that your welding machine is calibrated correctly and set to the appropriate welding mode and parameters. Adjust the current, gas flow rate, and other settings according to the specific requirements of the titanium welding process. Consult the equipment manufacturer’s guidelines or seek advice from experienced welders to ensure accurate and optimal machine setup.

Selecting the Appropriate Filler Metal

When welding titanium, selecting the appropriate filler metal is essential to ensure a strong and reliable weld. Different grades of titanium require specific filler metals with compatible mechanical properties. Consult the welding specifications and recommendations provided by the manufacturer to determine the most suitable filler metal for your project. Proper filler metal selection will guarantee a sound weld with excellent strength and corrosion resistance.

Preheating the Titanium

Titanium is an excellent conductor of heat and has a high melting point, which can make achieving proper fusion challenging. Preheating the titanium can help alleviate this issue by increasing the base metal temperature before the welding process begins. Preheating reduces the temperature gradient between the base metal and the weld pool, minimizing distortion and promoting better weld penetration. Follow the recommended preheating temperature and time guidelines to effectively prepare the titanium for welding.

By adhering to these crucial titanium welding preparation steps, you can improve the quality and integrity of your welds. Proper selection of welding methods, understanding titanium’s unique properties, ensuring proper ventilation, gathering essential tools and equipment, cleaning the welding area, preparing the titanium surface, securely positioning the workpiece, setting up the welding machine, selecting the appropriate filler metal, and preheating the titanium will contribute to successful titanium welding projects. Remember to always prioritize safety, closely follow recommended procedures, and consult experts or experienced welders for guidance when needed.