If you’re looking to weld titanium, it’s essential to follow a meticulous set of preparation steps to ensure a successful and strong bond. Titanium is a unique and challenging metal to weld, with its high melting point and reactivity to oxygen. To help you navigate the intricacies of titanium welding, this article will provide you with a comprehensive overview of the crucial preparation steps necessary for a successful weld. By meticulously adhering to these guidelines, you’ll be equipped with the knowledge and expertise to execute flawless titanium welds, becoming an authority in the field of welding. So, let’s delve into the world of titanium welding preparation steps and explore the key elements required for welding this extraordinary metal.

Titanium Welding Preparation Steps

Titanium welding requires careful preparation to ensure a successful and efficient welding process. By following the correct procedures, you can minimize the risk of welding defects and ensure the integrity of the weld. In this article, we will guide you through the essential steps to prepare for titanium welding. From understanding the welding process to selecting the appropriate filler metal, we will cover all aspects to help you achieve optimal results.

Understanding Titanium Welding

Before diving into the preparation steps, it is crucial to have a basic understanding of titanium welding. Titanium is a reactive metal that requires specific welding techniques and precautions. The heat generated during welding can cause oxygen and nitrogen to react with titanium, resulting in contamination and weakened welds. By understanding the unique characteristics of titanium and the challenges associated with its welding, you can better prepare for the process ahead.

Choosing the Right Welding Process

There are various welding processes available for titanium, including TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and electron beam welding. Each method has its own advantages and disadvantages, and the choice of process depends on factors such as material thickness, joint configuration, and desired weld quality. By carefully assessing these factors and understanding the capabilities of each welding process, you can select the most suitable one for your titanium welding project.

Selecting the Appropriate Filler Metal

When welding titanium, it is essential to use a filler metal that is compatible with the base metal. The most common filler metal for titanium welding is commercially pure titanium. However, there are also alloyed filler metals available that offer improved strength and corrosion resistance. The selection of the filler metal depends on the specific application and the desired mechanical properties of the weld. It is important to consult with welding professionals or refer to industry standards to ensure you choose the appropriate filler metal for your titanium welding project.

Ensuring Proper Ventilation

Titanium welding produces fumes and gases that can be harmful if inhaled. Therefore, it is crucial to ensure proper ventilation in the welding area. Adequate ventilation helps remove the welding fumes and provides a safe working environment. This can be achieved through the use of local exhaust ventilation systems or by working in a well-ventilated area with sufficient airflow. Additionally, wearing appropriate respiratory protection, such as a respirator, is essential to further minimize the risk of inhaling harmful fumes.

Gathering Essential Welding Tools and Equipment

Before starting the titanium welding process, it is important to gather all the necessary tools and equipment. This includes a welding machine suitable for titanium welding, welding cables, a TIG or MIG torch, an appropriate tungsten electrode, welding filler wire, gas cylinders, and a regulator. It is also essential to have various hand tools, such as pliers, wire cutters, and clamps, for proper joint preparation and handling of the titanium components. Having all the required tools and equipment readily available ensures a smooth and efficient welding process.

Cleaning and Preparing the Base Metal

Proper preparation of the base metal is crucial to achieve a sound and reliable weld. Titanium surfaces must be clean and free from contaminants, such as dirt, oil, grease, and oxides, before welding. These contaminants can negatively affect the quality and strength of the weld. The base metal should be meticulously cleaned using solvents, wire brushes, or abrasive pads to remove any surface impurities. Additionally, the joint surfaces should be properly prepared, ensuring a tight fit and good contact between the components.

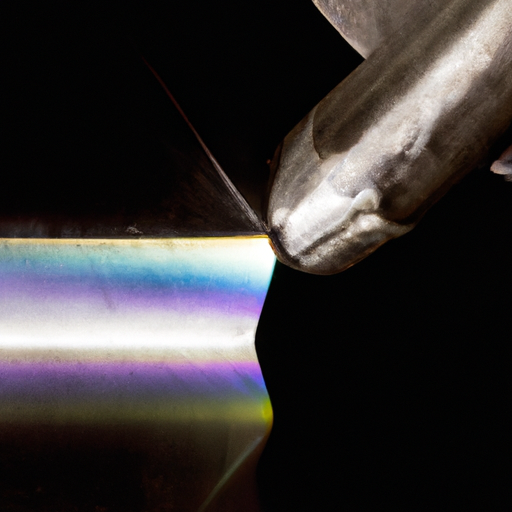

Determining the Welding Technique

The welding technique used for titanium depends on factors such as joint configuration, material thickness, and desired weld quality. TIG welding is commonly used for titanium welding due to its ability to produce high-quality welds with excellent control over heat input. However, alternative techniques, such as orbital welding or laser welding, may be more appropriate for certain applications. It is important to consider the specific requirements of the project and seek guidance from welding professionals to determine the most suitable welding technique.

Setting Up the Welding Area

Creating a suitable welding area is essential for a safe and effective titanium welding process. The welding area should be free from flammable materials and have sufficient lighting for clear visibility. It is important to ensure there are no combustible substances nearby that may pose a fire hazard. Additionally, the work surface should be clean, sturdy, and resistant to heat and sparks. Adequate shielding screens must be set up to protect nearby personnel and equipment from the intense light emitted during the welding process.

Preparing the Joint

Proper joint preparation is crucial to achieve strong and durable welds in titanium. The joint design and dimensions should be carefully considered to ensure sufficient weld penetration and strength. The joint surfaces should be properly cleaned and free from any gaps, as these can lead to incomplete fusion and weakened welds. In some cases, chamfering or beveling the joint edges may be necessary to facilitate proper filler metal distribution and control the weld’s shape. By thoroughly preparing the joint, you can ensure optimal weld quality and performance.

Inspecting Welding Equipment and Protective Gear

Before starting the titanium welding process, it is important to inspect all welding equipment and protective gear. Ensure that the welding machine is functioning properly and that all cables, connectors, and gas lines are secure. Check that the gas cylinders are in good condition and have sufficient gas supply. It is also crucial to inspect and wear appropriate personal protective equipment (PPE), such as welding helmets, gloves, and flame-resistant clothing, to protect yourself from the hazards associated with welding.

Validating Welding Preparations

Once you have completed all the necessary preparation steps, it is essential to validate your welding preparations before proceeding with the actual welding. This can be done by conducting a test weld on a sample joint to evaluate the weld quality and performance. The test weld should be visually inspected for any defects, such as cracks, porosity, or incomplete fusion. Additionally, mechanical testing, such as bend or tensile testing, can be performed to assess the weld’s mechanical properties. By validating your welding preparations, you can identify any potential issues early on and make necessary adjustments before starting the actual welding process.

In conclusion, proper preparation is key to successful and efficient titanium welding. Understanding the unique characteristics of titanium, selecting the appropriate welding process and filler metal, ensuring proper ventilation, gathering essential tools and equipment, and thoroughly cleaning and preparing the base metal are all crucial steps to achieve high-quality welds. By following these steps and validating your preparations, you can minimize the risk of welding defects and ensure the integrity of your titanium welds.