In the realm of welding, ensuring proper metal cleaning before the actual welding process is imperative for achieving high-quality and durable welds. From removing contaminants to reducing the risk of defects, pre-weld metal cleaning plays a crucial role in the overall welding process. This article aims to provide a comprehensive guide on the best practices for pre-weld metal cleaning, equipping you with the necessary knowledge to excel as an authority in the field of welding. By implementing these practices, you can enhance the integrity of your welds and deliver exceptional results. So, let’s delve into the realm of pre-welding metal cleaning and discover the techniques that will help you achieve welding excellence.

Importance of Pre-Welding Metal Cleaning

The significance of pre-welding metal cleaning

Pre-welding metal cleaning plays a crucial role in ensuring the quality and durability of welded joints. Before initiating the welding process, it is essential to thoroughly clean the metal surface to remove various contaminants and ensure proper weld adhesion. Failure to do so can result in weakened welds, weld defects, and reduced overall weld quality, compromising the integrity of the structure or component being welded.

Benefits of proper metal cleaning before welding

Proper metal cleaning before welding offers several benefits that contribute to the overall success of the welding operation. Firstly, it helps to remove surface contaminants that can negatively impact the weld, such as oxides, oil, grease, dirt, dust, paint, coatings, corrosion, and chemical residues. By eliminating these contaminants, the risk of weld defects, such as porosity, lack of fusion, and inclusions, is significantly reduced.

Moreover, pre-welding metal cleaning enhances weld adhesion, ensuring a strong and reliable bond between the base metal and the filler material. Proper cleaning prepares the metal surface by removing any barriers that could prevent the formation of a sound weld joint. Additionally, thorough metal cleaning helps to improve the overall aesthetics of the weld, resulting in a more visually appealing finished product.

Types of Metal Contaminants

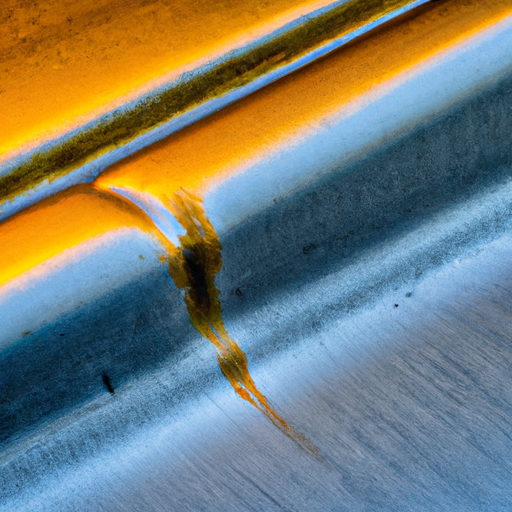

Surface oxides and scale

Surface oxides and scale are a common type of contaminant found on metal surfaces. These oxides are formed due to prolonged exposure to air and moisture, resulting in a layer of corrosion or rust. If not removed before welding, oxides can interfere with the fusion process, leading to weak or incomplete welds. It is essential to remove surface oxides and scale through proper cleaning methods to ensure a clean metal surface for welding.

Oil, grease, and other organic substances

Oil, grease, and other organic substances are often present on metal surfaces as a result of manufacturing processes, handling, or storage. These contaminants can act as a barrier, preventing proper adhesion of the filler material during welding. Furthermore, organic substances can lead to the formation of weld defects such as porosity, which weakens the weld joint. Thorough cleaning is necessary to remove these contaminants before welding to ensure a clean and contamination-free metal surface.

Dirt, dust, and foreign particulates

Dirt, dust, and foreign particulates can accumulate on metal surfaces due to various factors, including environmental conditions and improper storage. These contaminants can compromise the quality of the weld by creating voids or inclusions in the weld joint. Pre-welding metal cleaning should include the removal of dirt, dust, and foreign particulates to ensure the integrity and strength of the weld.

Paint, coatings, and residues

Paint, coatings, and residues are commonly found on metal surfaces, especially in manufacturing and fabrication industries. These substances can inhibit proper fusion during the welding process, resulting in weak welds. It is crucial to remove paint, coatings, and residues through effective cleaning methods to establish a clean and smooth metal surface for welding.

Corrosion and rust

Corrosion and rust are detrimental to the performance and strength of welds. Both processes can weaken the metal structure, leading to premature failure. Surface cleaning methods, such as acid pickling or abrasive blasting, can effectively remove corrosion and rust, ensuring a clean metal surface for welding.

Chemical residues

Chemical residues from previous manufacturing processes, such as cutting or machining, may be present on metal surfaces. These residues, if not removed, can negatively affect the welding operation by interfering with proper fusion and adhesion. Thorough cleaning utilizing appropriate chemical cleaning methods is essential to eliminate chemical residues before welding.

Inorganic contaminants

Inorganic contaminants, such as salts or minerals, can contaminate metal surfaces and adversely affect the welding process. These contaminants can promote the formation of weld defects and compromise the overall quality and strength of the weld. Adequate cleaning methods, such as electrolytic cleaning or solvent cleaning, should be employed to remove inorganic contaminants before welding.

Common Pre-Welding Metal Cleaning Methods

Mechanical cleaning methods

Mechanical cleaning methods involve physically removing contaminants from the metal surface using tools such as wire brushes, sandpaper, or grinding wheels. These methods are effective for removing surface oxides, scale, paint, and coatings. Mechanical cleaning should be performed carefully to avoid damaging the metal surface or introducing new contaminants.

Chemical cleaning methods

Chemical cleaning methods utilize chemical solutions or agents to dissolve or remove contaminants from the metal surface. This method is particularly useful for removing oil, grease, organic substances, and chemical residues. Chemical cleaning methods should be performed with caution, ensuring appropriate safety precautions and proper disposal of cleaning solutions.

Electrolytic cleaning methods

Electrolytic cleaning involves using an electric current to remove contaminants from the metal surface. This method is effective for removing oxides, scale, and inorganic contaminants. Electrolytic cleaning offers the advantage of being a controlled and precise cleaning process, but it requires specialized equipment and expertise to ensure optimal results.

Ultrasonic cleaning

Ultrasonic cleaning utilizes high-frequency sound waves to create microscopic bubbles in a cleaning solution, which agitate and dislodge contaminants from the metal surface. This method is highly effective for removing dirt, dust, and organic substances. Ultrasonic cleaning is particularly useful for cleaning intricate or hard-to-reach areas.

Vapor degreasing

Vapor degreasing involves using heated solvents or solvent vapors to dissolve and remove oil, grease, and other organic substances from the metal surface. This method is efficient, quick, and suitable for large-scale cleaning operations. Proper ventilation and safety precautions should be taken when performing vapor degreasing.

Acid pickling

Acid pickling utilizes acid solutions, such as hydrochloric acid or sulfuric acid, to remove surface oxides, scale, and corrosion from the metal surface. Acid pickling is highly effective in restoring the cleanliness and integrity of metal surfaces. However, proper safety measures must be followed when handling and disposing of acidic solutions.

Abrasive blasting

Abrasive blasting involves using high-velocity abrasive particles, such as sand, grit, or glass beads, to remove contaminants from the metal surface. This method is useful for removing paint, coatings, rust, and stubborn debris. Abrasive blasting should be performed by trained professionals and with appropriate safety equipment to protect against airborne particles.

Solvent cleaning

Solvent cleaning utilizes liquid solvents to dissolve and remove contaminants from the metal surface. This method is effective for removing oil, grease, and organic substances. It is important to choose the appropriate solvent based on the type of contaminant and follow safety guidelines for handling and disposal.

Flame cleaning

Flame cleaning involves using a high-temperature flame to burn off contaminants from the metal surface. This method is primarily used for removing organic substances, such as paint or coatings. Flame cleaning should only be performed on metals that can withstand high temperatures and in well-ventilated areas to prevent the inhalation of toxic fumes.

(Continued in next response…)